Textile Energy saving solutions

In almost all manufacturing processes, textile mills need compressed air to make those beautiful, colorful fabrics. In particular, the cotton textile industry, which uses air-jet looms, and the polyester yarn industry require a lot of air.

The consumption of compressed air in the textile industry is increasing as a result of the modernization of production processes. It is used for almost all machine operation and control. In order to ensure the economical and continuous production of high

Example of compressed air in textile factory.

> Air-jet weaving

> Spinning frame

> Artificial fiber production

> Texture processing

> Stacking device

> Printing press

> Thread detector

> Sewing machine

The textile industry saves a lot of compressed air

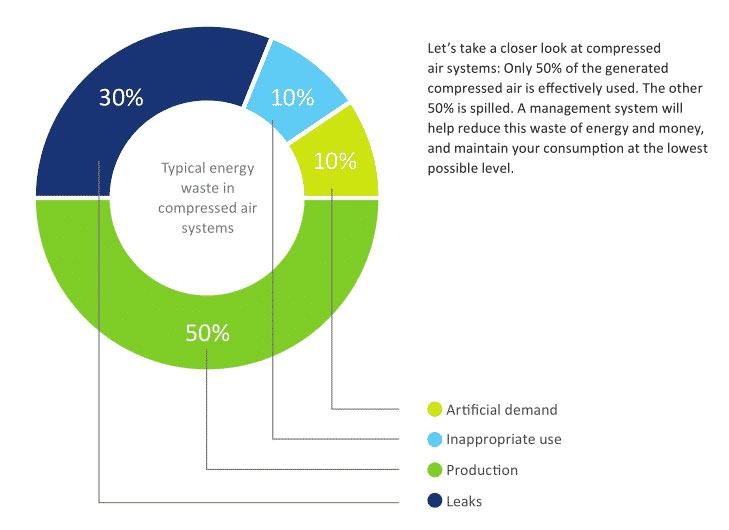

Because compressed air is such an important utility in these plants, improving the use of compressed air will yield significant economic benefits. Eliminating leaks and reducing working pressure are two of the most cost-effective steps you can take to save energy. Through the correct selection and effective management of compressed air systems, including compressors, air handling and filtration units, distribution networks and end-use, the diverse processes of spinning, weaving and processing hold great potential for cost savings in the textile industry without any widespread impact on factory productivity and product quality.

Any improvement step starts with measurement and monitoring.

More information and related cases

For domestic enterprises of green energy conservation

Industry makes its own contribution

By searching on the website, you will receive the latest information on industry trends and developments, our products and solutions,

And information about our trade fair.