- Overview

- Specification

- Manual

Technical introduction

Our company introduces the Nordic advanced energy-saving concepts, methods, tools and technologies of compressed air system, realizes "technology energy saving + management energy saving" through big data analysis, tailor-made energy-saving optimization scheme for enterprises, and adopts a series of effective concrete means to optimize the operation of compressed air system, and finally achieves the purpose of accurate energy saving by improving the comprehensive energy efficiency of the system. According to the system energy use situation of different enterprises, the energy saving rate of compressed air system can be usually achieved by 10%~35%.

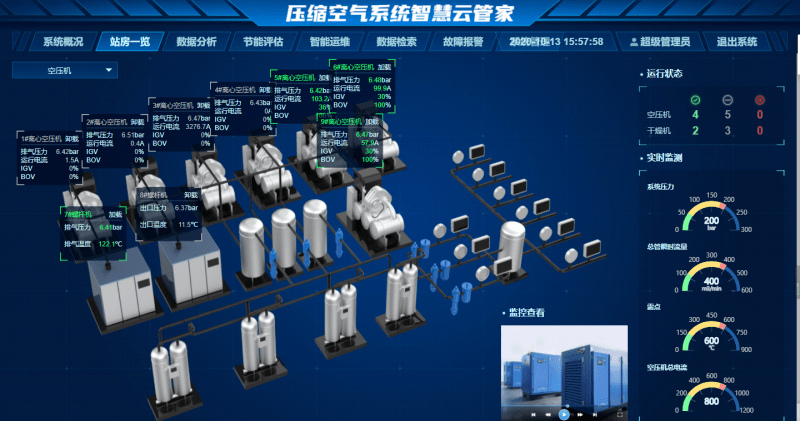

Technical schematic diagram

#FormatImgID_0#

The compressed air system energy saving cloud platform technology consists of a whole set of service processes. It installs a series of metering instruments on the compressed air system of industrial enterprises, collects the key parts of the compressed air system including pressure, flow rate, dew point, temperature and other parameters, uploades the data to the energy efficiency platform through cloud technology, and carries out multi-dimensional display and analysis of the data, combined with a rich team of experts The experience will eventually form the accurate diagnosis of the energy use of the compressed air system, and the overall solution of energy efficiency improvement will be tailored for enterprises to achieve the purpose of accurate energy saving.

Technological advantage

It breaks through the limitation of "single machine" energy saving and takes "system" as the whole object to save energy.

Based on the data, the accumulation and analysis of big data and the experience of international experts, starting from the leakage management, reduce and control the leakage amount of the customer's end, so that the whole air compressor system can supply gas on demand, and then customize the overall energy saving plan for the customer;

From the technical and management aspects of precision, sustainable energy conservation, constantly optimize the system operation, to achieve and maintain energy efficiency "maximization".

Application field

It is suitable for all industrial enterprises with compressed air system and energy saving requirement.

Implementation case

Hankook Tire (Jiaxing) Co., LTD

Through the installation of the compressed air system energy efficiency supervision platform, the analysis and diagnosis of the implementation of "leakage management", "air compressor operation optimization", "dryer optimization", "supply and demand pressure optimization" and other transformation measures.

By comparing the original unit of air compressor power consumption/tire output, the energy consumption of air compressor decreased by 25% from July 2019 to August 2020. Reduced electricity cost by 5 million yuan per year.

Beijing BOE Optoelectronic Technology Co. LTD

Based on the results of big data analysis, seven energy-saving optimization measures are proposed. After implementation:

The basic energy saving transformation has achieved an energy saving rate of 13% and electricity saving of 3.6 million yuan/year.

Rolling transformation energy-saving rate increased to 19%, saving electricity 4.85 million yuan/year.

Continuous optimization goal: electricity saving 5.7 million/year (to the end of 2018).