浅谈流量计的现场精度

发布日期:2023-04-03 访问量:2164

发布日期:2023-04-03 访问量:2164

浅谈流量计的现场精度

当谈到流量计的精度时,具备一些基本的知识,能够了解是什么影响它很重要。我们在社交平台上看到了很多讨论,人们在没有讲述真实故事的情况下就对其准确性做出了评价。在本文中,我们将为您提供一些常见问题的实用答案。

在一些关于流量计的讨论中,我们看到的表述

比如:“用我们的流量计,你只需要上游管段10到15倍

直径”。事实上,这是不可能的,

使用“单点型”流量计用点测量压缩空气或气体。这有违

其基本物理特性。

那么,什么是“点测量/单点型”流量计呢?

这些流量计都是基于在一个点的速度测量从而计算出流量。一个明显的例子是插入式流量计,它是审计中最常用的流量计类型之一。另一个例子,从外部看不那么明显,是超声波钳式测量仪。这个流量计还可以测量一条直通路上的流量。一些仪表测量流量使用更先进的技术,如双通路,甚至多通路,但这些在压缩空气应用中不太常用。

Field accuracy vs. specifications

现场精度

In compressed air applications, even the most accurate flow meter can be misapplied, which may result in large systematic errors or random erratic readings. In compressed air flow audits, especially in old, existing compressed air systems, obtaining realistic measurement data can be a very tricky

thing, as all “spot measurement type” flow meters are prone to up- and downstream disturbances. These disturbances are often causing large deviations.

在压缩空气应用中,即使是最精确的流量计也可能被错误应用,这可能导致大的系统误差或随机的不稳定读数。在压缩空气流量审计中,特别是在旧的、现有的压缩空气系统中,获取真实的测量数据可能是非常棘手的。

所有的“点测量型”流量计都容易受到上游和下游的干扰。这些干扰常常造成很大的偏差。

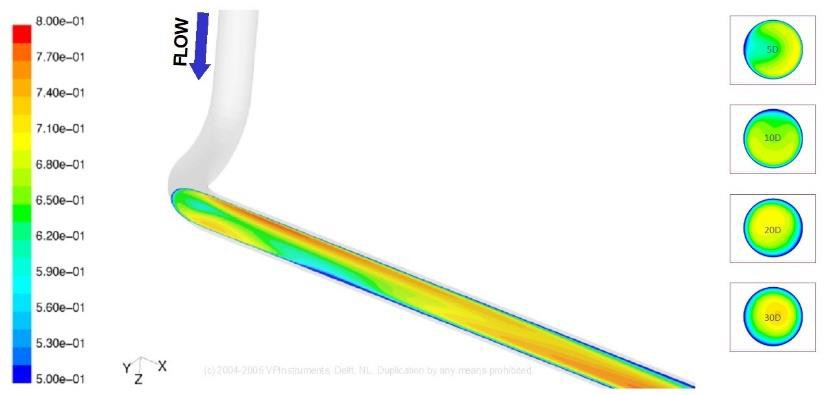

Examples of items that can disturb the flow profile are double elbows, abrupt diameter changes, and large T-pieces. In many cases, the customer can only place the flow meter 5 or 10 diameters downstream of these items, which will have a large influence on the field accuracy.

可能干扰流动剖面的例子有双弯管、突然的直径变化和大的T型口。在很多情况下,客户只能将流量计放置在这些项目下游5或10倍直径管段的地方,这将对现场精度有很大的影响。

The perfect installation spot in existing factories is often a challenge.

A flow meter is calibrated under ideal conditions, which means it will be subjected to a known, symmetric velocity profile in a reference pipe with known inner diameter. But when you have to install a flow meter in a pipe on a too

short distance from potential disturbances we advise you to add at least 5% to 10% to your uncertainty budget and make sure all parties involved are aware of the additional measurement uncertainty. Especially when “testing” compressor performance in the field, one needs to be very careful.

流量计是在理想条件下校准的,这意味着它将在一个已知内径的管道中受一个已知的、对称的速度剖面。但是当你不得不在很短的上下游管段上安装一个流量计的时候

我们建议您在不确定度误差中增加至少5%到10%,并确保所有相关方都知道额外的测量不确定度。特别是在现场“测试”压缩机性能时,需要非常小心。

Turbulent vs. Laminar

紊流和层流

We still hear people talking about “laminar flow” in compressed air. Let’s get this straightened out as well. Did you know that compressed air, due to the high velocities and large pipes, is always turbulent? In compressed air networks, you will never reach laminar flow unless you are measuring very low velocities. Why? Because of another law of Physics, which is described by Reynolds and

others. But don’t worry, it is not a problem at all. It actually has an advantage, as the flow profile is

rather flat instead of parabolic. Which makes insertion of your flow meter less critical in larger pipes.

我们仍然听到人们谈论压缩空气中的“层流”,让我们把这个也弄清楚。你知道压缩空气,由于高速和大管道,总是紊流吗?在压缩空气网络中,除非测量非常低的速度,否则永远不会达到层流。为什么?因为另一个物理定律,由雷诺兹等人描述。但别担心,这根本不是问题。它实际上有一个优势,因为流动曲线相当平坦,而不是抛物线。这使得在更大的管道中使用插入式流量计变得不那么受影响。

From now on, we should talk “fully developed” flow, instead of laminar, which means the flow profile is nicely symmetric, equally distributed over the pipe surface. It will take quite some length to become symmetric, in some cases, especially with double elbows out of plane, we have seen that it takes up to 60 D.

从现在开始,我们应该讨论“完全发展”的流量,而不是层流,这意味着流量剖面是非常对称的,均匀分布在管道表面。它需要相当长的直管段长度才能对称,在某些情况下,特别是在有些双弯管情况下,我们已经看到形成完全发展的流量需要60倍管径。

Flow meter technologies compared – things to be aware of

流量计技术比较-需要注意的事情

Thermal insertion probes: flow profile effects and temperature effects. Sudden changes in temperature can influence the measurement. Water drops will give spikes in the measurement signal.

热式质量插入式探头:流量剖面和温度影响。温度的突然变化会影响测量。水滴会在测量信号中产生尖峰。

Differential pressure probes: flow profile, turndown ratio is limited, be aware of low flow. Water drops and dirt might clog pressure ports. Water in connecting pipework can give strange results.

差压式探头:流量剖面和调节比有限,需注意低流量。水珠和污垢可能会堵塞压力端口。连接管道的水可能会对结果产生影响。

Ultrasound: Flow profile, ultrasonic noise from valves, vibration, signal loss.

超声波:流量剖面,阀门超声波噪声,振动,信号丢失。

Vortex (in-line): Water drops, turndown ratio is limited, be aware of low flow and permanent pressure loss over the meter

涡街(在线):水滴,调节比有限,需注意低流量和压力损失。

Differential pressure (in line): Limited turndown, be aware of low flow. Permanent pressure loss when using orifice type meters.

差压(管道式):有限的调节比,需注意低流量。当使用孔板式仪表时,有永久性的压力损失。

Turbines: Oscillation can give higher or lower average flow values. Pressure pulses might damage the bearings. Water can cause corrosion, causing misreadings.

涡轮:振荡可能会给出更高或更低的平均流量值。压力脉冲可能损坏轴承。水会引起腐蚀,导致读数错误。

How accurate do you need to be?

你需要多精确?

In an audit, it depends on what you are looking for (leaks, demand profile, compressor control system performance, compressor efficiency). When analyzing the data, it is all about the auditor skills, and how the auditor interprets the combination between various sensors and signals.

在审计中,这取决于你在寻找什么(泄漏,需求概况,压缩机控制系统性能,压缩机效率)。在分析数据时,关键是审计员的技能,以及审计员如何解释各种传感器和信号之间的组合。

Sometimes, a simple load/unload signal of a compressor can already provide insight in the control system behavior, in other cases you might want to zoom into the demand side, where you need a bi- directional flow meter. The more signals you combine, the more clarity you will get about what is going on exactly.

有时,空压机的一个简单的负载/卸载信号已经可以提供对控制系统行为的洞察,在其他情况下,您可能想要放大到需求端,在那里您需要一个双向流量计。你结合的信号越多,你就越能清楚地了解到底发生了什么。

In general, 5% accuracy is fine for an air audit using insertion probes, taken all uncertainties into account. If you want to test a compressor in the field, and compare it to factory specs, you must check the ISO 1217 directive on the required accuracy. This might require special equipment and specialized people to carry out the test.

一般来说,考虑到所有的不确定性,5%的准确度对于使用插入式流量计的空气审计来说是很好的。如果您想在现场测试压缩机,并将其与工厂规格进行比较,您必须检查ISO 1217指令所要求的精度。这可能需要专门的设备和专业人员来进行测试。

Need some advice?

需要一些建议吗?

Contact us to discuss your application. We will be happy to advise you with selecting the right product, which might not be a flow meter in some cases.

联系我们,一起来讨论您的申请。我们将很高兴地为您选择正确的产品。

- 上一篇:上一篇:压缩空气系统KPI的测量原则

- 下一篇:下一篇:双向压缩空气流量测量的重要性

为国内企业的绿色节能事

业做出自己的贡献

通过网站的搜索,您将收到有关各行业趋势和发展的最新信息,我们的产品和解决方案,

以及我们的贸易展览会的信息。